Why us ?

Rosa is a family-run business driven by quality and sustainability since it’s very start. With 70+ years of history and an uncompromising passion, we are the unique historical business in southern France that has managed to keep a successful cork industrial unit on the French Riviera. We are proudly providing customised products and technical solutions for a wide range of demanding industries such as : green-building, wine, electronics, energy…

Focused on cork, our area of expertise covers : raw material, cork stoppers, cork composites, flooring and wall coverings, thermal and acoustic insulation, packaging and various technical applications.

Sustainability has always been the core value of our company. We believe children deserve healthy playgrounds, and a liveable planet in the meantime. That’s why we proudly support the Sea Shepherd foundation, which sole mission is to defend the marine wildlife worldwide. To help them in their fight, we are happy to donate 1% of our yearly profits.

Curious and passionate, our team is always looking for the next green idea, and we love to present cork to our customers as a disruptive natural solution. When it comes to children playgrounds, Green Grounds™ clearly pushes boundaries by offering the first outdoor surfacing solution which is 100% sustainable and 100% safe.

The very nature of our busines is to promote one of the most sustainable raw material available on earth. In the same ecological state of mind, when designing and manufacturing a cork solution we are constantly focused on its crade-to-grave impact. The results speak for themselves :

![]() 50% of the Top layer comes directly from our surrounding forests (within a 35 km radius).

50% of the Top layer comes directly from our surrounding forests (within a 35 km radius).

![]() 50% of the Top layer is made from recycled cork (cork wastes coming from Wine stoppers manufacturing).

50% of the Top layer is made from recycled cork (cork wastes coming from Wine stoppers manufacturing).

![]() Base and Top layers are 100% recyclable. In addition, the process of recycling is extremely easy and can be performed by hundreds of industrial units accross Europe, by low-energy mechanical means.

Base and Top layers are 100% recyclable. In addition, the process of recycling is extremely easy and can be performed by hundreds of industrial units accross Europe, by low-energy mechanical means.

![]() We make the most from the French Riviera sun, with 312 square meters of solar panels on our roofs. Since 2011, we have produced 60 000 kWh each year, covering about 80% of our electrical needs.

We make the most from the French Riviera sun, with 312 square meters of solar panels on our roofs. Since 2011, we have produced 60 000 kWh each year, covering about 80% of our electrical needs.

![]() Low embodied energy to produce our cork granules. Over the years, we have made a thorough selection of low-energy consuming solutions for manufacturing, conveying and packing Green Grounds™.

Low embodied energy to produce our cork granules. Over the years, we have made a thorough selection of low-energy consuming solutions for manufacturing, conveying and packing Green Grounds™.

![]() Optimized particle-size distribution : years of R&D enabled us to spot the right balance between binder consumption, fall protection, and lifespan of our surfacing compound.

Optimized particle-size distribution : years of R&D enabled us to spot the right balance between binder consumption, fall protection, and lifespan of our surfacing compound.

![]() Light weight : on average, the Base and Top layers offers a 65 kg/m3 density, about 7x less than for EPDM or SBR. This lightness drastically lowers the energy for transport compared to the synthetic compounds.

Light weight : on average, the Base and Top layers offers a 65 kg/m3 density, about 7x less than for EPDM or SBR. This lightness drastically lowers the energy for transport compared to the synthetic compounds.

![]() Packaging : minimalist and recycled kraft-paper bags, 100% recyclable.

Packaging : minimalist and recycled kraft-paper bags, 100% recyclable.

When it comes to quality, we never compromise.

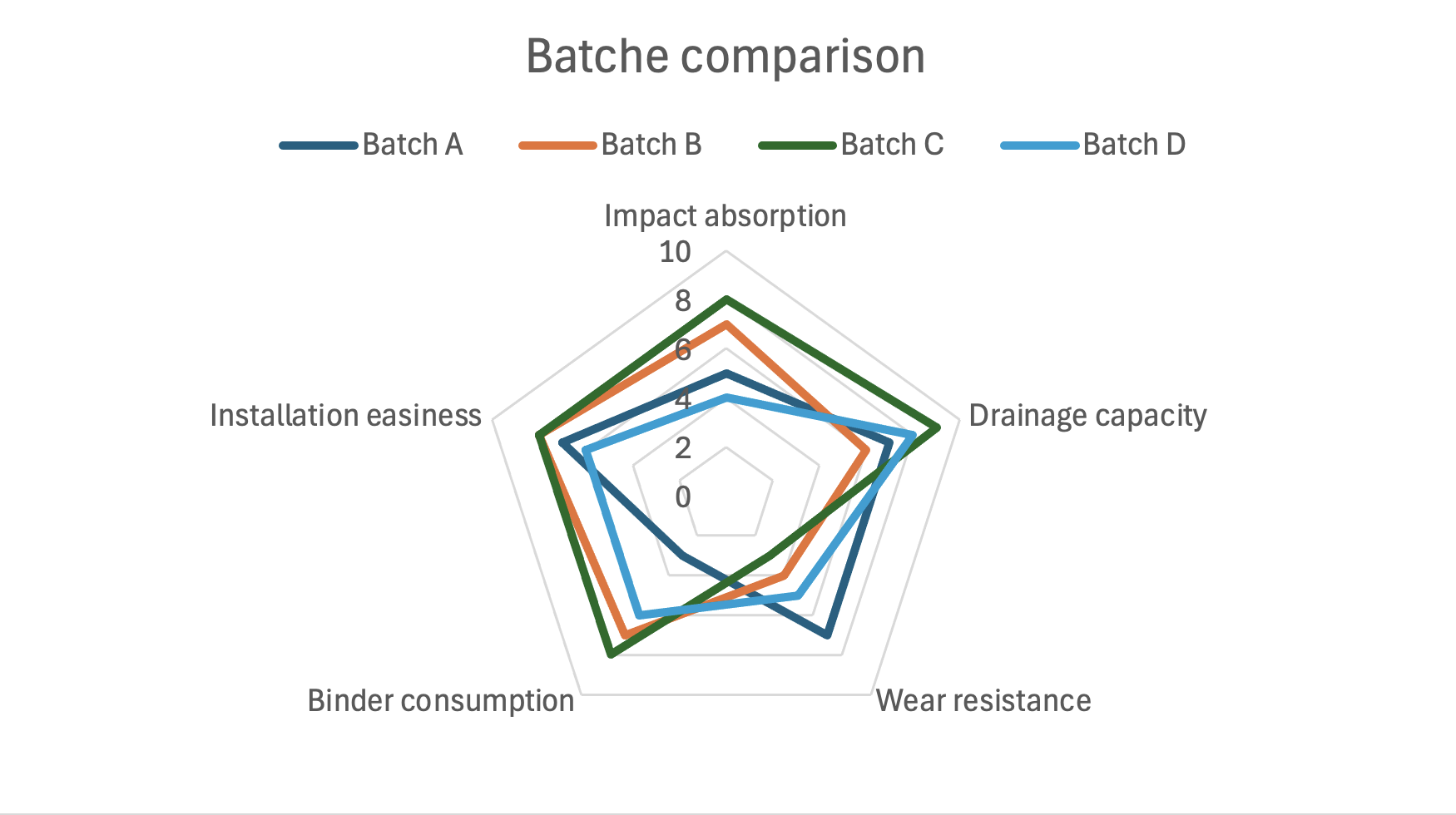

Years of R&D enabled us to identify the perfect balance between fall protection, binder consumption, and lifespan of our surfacing compound.

We have 70+ years of experience in transforming an heterogeneous raw material into a fully standardised and reliable homogeneous product. We can guarantee identical features from one batch to the other thanks to a carefully designed manufacturing process. We manage critical factors through a drastic quality policy which encompass :

![]() Active de-dusting™ : when dealing with cork particles, dedusting is a key element to guarantee free from soil (soil is naturally found in cork lenticels) and free from cork dust granules. Over the years, we have developed a unique in-houseprocess to remove soil and dust particles from our cork granules. This de-dusting process is our little secret, enabling us to guarantee a hassle-free laying (less dust = better distribution and drying of the binder) and a high impact absorption (cork dust offers poor elasticity).

Active de-dusting™ : when dealing with cork particles, dedusting is a key element to guarantee free from soil (soil is naturally found in cork lenticels) and free from cork dust granules. Over the years, we have developed a unique in-houseprocess to remove soil and dust particles from our cork granules. This de-dusting process is our little secret, enabling us to guarantee a hassle-free laying (less dust = better distribution and drying of the binder) and a high impact absorption (cork dust offers poor elasticity).

![]() Moisture content : when applying the binder-granule mix, you do not want an excess of water to ruin the curing process. In the first place, this is why we opted for expanded cork granules as our Base layer : those granules contains less than 4 % of water. In addition, the natural cork granules used for the Top layer are controled throughout the manufacturing process to ensure a moisture content below 13% 1

Moisture content : when applying the binder-granule mix, you do not want an excess of water to ruin the curing process. In the first place, this is why we opted for expanded cork granules as our Base layer : those granules contains less than 4 % of water. In addition, the natural cork granules used for the Top layer are controled throughout the manufacturing process to ensure a moisture content below 13% 1

![]() Particle-size distribution : when looking for the perfect playground surface, we must address three critical issues : shock absorption, wear-resistance and binder consumption. Years of R&D enabled us to select the ideal particle-size distribution for each layer, providing an optimised solution.

Particle-size distribution : when looking for the perfect playground surface, we must address three critical issues : shock absorption, wear-resistance and binder consumption. Years of R&D enabled us to select the ideal particle-size distribution for each layer, providing an optimised solution.

![]() Quality management : our inspection is key to guaranteeing an homogeneous compound. We implement a thorough inspection plan, by checking very regularly density, moisture content and particle-size distribution (more information upon request)

Quality management : our inspection is key to guaranteeing an homogeneous compound. We implement a thorough inspection plan, by checking very regularly density, moisture content and particle-size distribution (more information upon request)

1 : Moisture content is « ex-factory » guaranteed. Moisture content may vary according to transport, storage, and weather conditions during the laying.